In early February as COVID-19 started its spread, people quickly adopted to a new normal — keeping physical distance, handwashing frequently, and diligently wiping down surfaces. Sales of hand sanitizer skyrocketed, and shoppers rushed to find empty shelves as retailers could not keep the germ-killing necessity in stock. With people desperate to get their hands on this newly hot commodity, a critical tool in flattening the curve of the pandemic, local distillers across the country stepped up to fill the void. Distilleries were well-equipped and had the permits to either buy or make ethyl alcohol, the key ingredient in hand sanitizer that kills germs.

Mike Allenbach, owner of Skybound Spirits Distillery in Seattle, and Johnny Bianchi, owner of Industry Space, a 60,000 square foot manufacturing startup and incubator space, saw an opportunity to pool their resources to make a difference. Between the two of them, they had 300 gallons of 200 proof ethyl alcohol ready to go, and the space, equipment, and connections to hit the ground running.

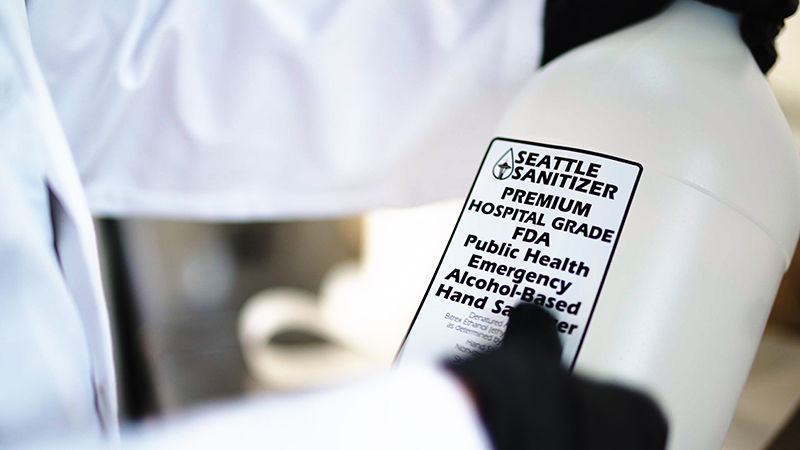

They brought Stephan Howard on board as a partner, and got to work quickly, mixing a five-gallon prototype pail of sanitizer before meeting with a representative from the city of Seattle’s Office of Economic Development who gave the partners the Federal Drug Administration (FDA) guidance regulation to start brewing the germ-killing elixir. From there, Seattle Sanitizer was born.

“With our assets, distillery and production, we made 300 gallons the first night,” Bianchi said. “This was very exciting because at the time sanitizer was unattainable to people.”

Good spirits

As they shifted from crafting Skybound’s signature Seattle Seafair Pirate Rum to distilling their new concoction, the sanitizer flew off the shelves. The first wave of hand sanitizer went to 70 different municipalities, law enforcement agencies, hospitals, grocery store chains throughout the country, and the Port of Seattle and Seattle-Tacoma International Airport (SEA). To date, the Port has purchased 200 gallons of sanitizer from Seattle Sanitizer.

Law enforcement agencies, desperate to fill the hand sanitizer void and keep employees safe, rushed from locations across the state to Bianchi’s South Park warehouse to pick up their hand sanitizer orders.

“A man who worked at one of the local corrections facilities was in tears talking about how they didn’t have hand sanitizer and he couldn’t send his employees home; it just wasn’t an option for them to say ‘we’re not doing jail today,’” Bianchi said. “He felt like they had discovered a goldmine when they found us. It left us feeling like we were doing good.”

Germ proof

To develop their hospital-grade disinfectant, Allenbach and Bianchi source USP (United States Pharmacopeia) grade ethyl alcohol — a high-quality sustainable ethyl alcohol source made from potato and corn processing plant leftovers.

Seattle Sanitizer’s formula contains 85 percent ethyl alcohol, which destroys germs and bacteria in seconds. Many mass- marketed hand sanitizers are made with just 60 percent ethyl alcohol. The weaker formula may take up to three or four minutes to kill germs and bacteria.

Seattle Sanitizer is a liquid formula rather than a gel, which packs an extra germ-fighting punch, allowing the sanitizer to soak into cracks and crevices of hands or surfaces and eliminating any hard to reach bacteria.

“We went for the maximum efficacy level, which gave us a hospital grade product that kills germs and bacteria quicker than off-the-shelf products,” Bianchi said.

Their best shot

“At our peak, we were bottling just shy of 10,000 gallons a week. We got it produced, bottled, and out the door,” Allenbach said. “Now we are focusing on small bottles, which are pretty time consuming. They don’t fill up as fast some of our larger containers.”

Allenbach and Bianchi are also working on two sanitizer dispenser prototypes for municipal or large public areas. The prototypes are mechanical and vandal-proof which makes them a natural fit for the wear and tear of city streets.

Allenbach said it has been rewarding to provide a way for people to stay healthy during uncertain times.

“The use of sanitizer has curbed the disease in a pretty real way; I have never been part of an operation of this scale,” he said. “It’s kind of like being shot out of a cannon. Going right into giant production from day one was fun and exciting. It was nice to do something to help while everyone was sheltering in place.”

Bianchi said he is thankful for the support from those who bought their sanitizer early on, which has helped legitimize their business and allowed them to build out their product.

“This is all done here in Seattle. It’s done by people who live here and have grown up here. We take pride in doing something that keeps people safe in our community,” Bianchi said. “I’m happy to be some part of a solution that’s helping people get through this crisis.”