Updated February 2022

SEA kicks off a monumental year with a record-breaking construction project on the International Arrivals Facility (IAF). One of the most iconic elements — and one of the most complicated engineering challenges of the decade at SEA — is an elevated pedestrian walkway that will rise 85 feet over an active taxi lane with planes traveling underneath.

This new facility, launched in 2022, is a huge step towards improving the passenger experience and is a modern facility that will welcome a growing number of international travelers to a region known for its innovation. The IAF will make the international arrivals process far more efficient, providing direct passage for international travelers arriving at the South Satellite to the new customs processing facility. It will also welcome travelers with stunning views through the glass walkway of the natural beauty of the Pacific Northwest like Mount Rainier and the green landscape.

After nearly eight years of planning, design, and construction, the entire aerial walkway will soon be visible to SEA travelers at the south end of the airport, near Concourses A and B and the South Satellite. To better appreciate this modern marvel in the making, here are five fast facts about the IAF pedestrian walkway.

1. It’s the world’s longest structure over an active taxilane

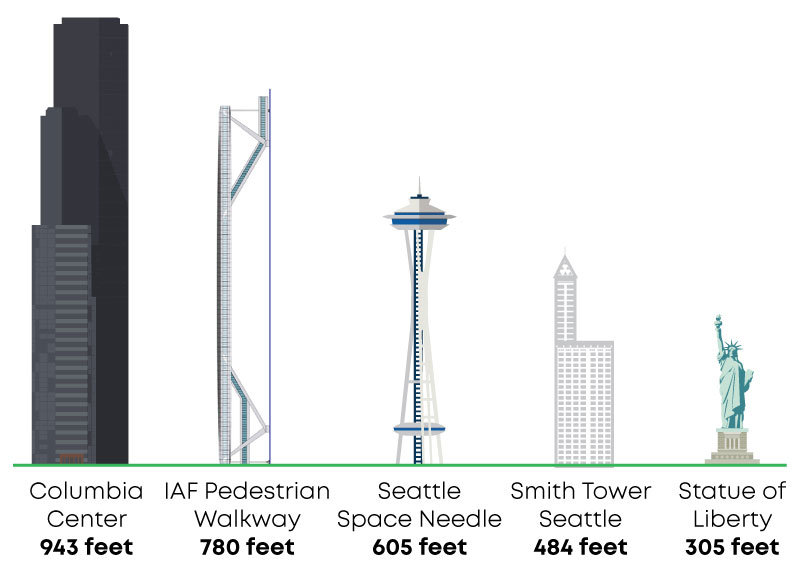

Building a bridge across a busy airport taxilane has only been completed at three airports in the world. The Pacific Northwest is known for its technical innovation, so we’re going big and breaking the record — once completed, the 780-foot-long aerial walkway will be the longest structure over an active taxilane in the world! The current record is held by Gatwick Airport’s Pier 6 pedestrian walkway at 650 feet.

2. It’s one of the tallest mega structures in the region

When standing on end, the IAF pedestrian walkway would be one of the tallest structures in Seattle — more than 150 feet taller than the height of the Space Needle.

3. It’s one of the longest clear spans for this type of structure

The clear span of a structure is the unobstructed distance between two supports, and the IAF aerial walkway’s clear span is a massive 610 feet. Typical construction would have additional supports along the span. This width and the aerial walkway’s 85-foot vertical clearance allow for an aircraft’s wingspan and tailfin (even for jets like the 747-400) to safely pass underneath the structure.

For construction nerds who want to know more about this structural feat, the aerial walkway was designed as a cable-stayed bridge and the Accelerated Bridge Construction (ABC) method was applied for the build.

To learn more about the ABC method, visit:

- Washington State Department of Transportation ABC Building Resources

- U.S. Department of Transportation ABC Resources

4. It was built offsite and is a major construction achievement in steel fabrication and field welding

As part of the Accelerated Bridge Construction method, the pedestrian walkway was built offsite in multiple pieces or pre-fabricated components. Overall, there were 17 major pre-fabricated components that make up the pedestrian walkway structure. The structural steel used in the entire walkway alone weighs 3,000 tons. At an average weight of five tons, that’s the equivalent of 600 African elephants!

Seven steel fabricators, all located within a three-hour radius of the project site, crafted and contributed components of the walkway. Steel fabrication is a challenge in itself, but assembling the structure on-site presents its own challenges to meet safety and engineering tolerances that ensure quality construction. One specific example is the size and thickness of the steel, which creates some of the largest and most difficult welding situations in the industry. Many of these individual steel pieces weigh from 130 to 170 tons, come in difficult angles, and their welds can be up to six feet in length and 3.5 inches deep. These welds are critical for the structure’s strength and must meet stringent welding codes before they are signed off.

The most complex pre-fabricated component of the walkway is the center span (pictured below), which was built off-site on the north end of the airfield, nearly two miles from away from the bridge location.

5. Assembly and installation will be as challenging as moving 14 blue whales

The middle section (or center span) of the pedestrian walkway measures 320 feet (the length of a football field) and weighs 1,560 tons (equivalent to 14 blue whales). Built north of the IAF project site at Cargo 2, precise planning has gone into the movement and installation of this mega structure.

The walkway center span will be carried by four remote-controlled transporters (known as self-propelled modular transporters, SPMTs). Traveling at walking-speed from Cargo 2, they will maneuver down the closed center runway to reach the bridge’s final destination between the South Satellite and new facility. This highly sensitive and choreographed operation will take place in the early morning hours so it doesn’t interfere with your travel plans.

Before the center span can be lifted into place, there are several hours of site checks needed to ensure the pre-fabricated center span lines up with the existing V-piers. Once complete, four strand jacks will lift the center span into place. The motion of the lift is similar to a bucket of water being hauled up a well and will be lifted at a rate of 20 feet per hour.

Video courtesy of Clark Construction

BONUS FACT: IAF pedestrian walkway escalators will rank among the top 10 longest in the U.S.

There are five escalators total in the elevated pedestrian walkway. The escalators transporting travelers from the South Satellite to the aerial walkway will measure in at 191 feet long with an 80-foot rise.

Other escalators known for their length, include:

- Longest in the U.S. — Located in Wheaton, Maryland, Washington D.C. Metro System’s Wheaton Station has the longest escalator in the U.S. measuring in at 230 feet long with a 115-foot rise.

- Longest in the world — Located in St. Petersburg, Russia, the Moscow Metro’s Park Pobedy Station has the longest escalator in the world measuring in at 453 feet long with a 226-foot rise.

We’re not suggesting that you take an overseas journey just to see this amazing facility. But it just may be worth it!

The IAF Pedestrian Walkway would not be possible without the hard work and dedication of the project team led by Design-Builder Clark Construction Group. The project team includes the following designers, engineers, subcontractors, trades, and subject matter experts:

- Clark Construction Group – Design-builder

- SOM (Skidmore, Owings & Merrill) – Designer

- KPFF – Structural Engineer / Engineer of Record

- SBP – Structural Consultant

- The Erection Company (TEC) - Walkway Steel Assembly

- Steel Fabricators:

- Conco – Concrete cores and slab on metal deck

- Crown Corr – Curtain wall and metal panel erection

- Mammoet – Pedestrian walkway move from Cargo 2 to final installation

- Allyn Kilsheimer (KCE Structural Engineers) – Third-party reviewer of erection plan

- Condon-Johnson – Deep foundations

- American Fireproofing – Fireproofing

- Mayes Testing – Third-Party Testing