By Hannah Tennent, Port Maritime Environment and Sustainability Intern

A bench in Centennial Park is the perfect spot to watch colorful cruise and cargo ships move around Elliott Bay against the backdrop of the Olympic mountains. These ships are large, ranging in length from 900 to 1400 feet — longer than the height of the Space Needle at 600 feet tall. They also travel long distances, from 900 nautical miles for a cruise ship sailing from Seattle to Juneau, to more than 20,000 nautical miles for a container or bulk cargo ship traveling to ports in Asia. It takes a lot of energy to propel these large, “oceangoing” vessels, as they are called, through the water to their distant destinations.

Most oceangoing vessels you see are powered by fossil fuels made from petroleum. However, as the climate emergency grows, so does the urgency to transition to low and zero-greenhouse gas (GHG) emission energy sources across all sectors of the economy, including the maritime industries. Currently, there is not one clear pathway to power oceangoing vessels from cleaner sources of energy, and no zero-emission technology or fuel commercially available at scale. However, several low- and zero-Greenhouse Gas (GHG) emission fuels are emerging, and research, development, and demonstration projects are testing these fuels in maritime applications. Here’s an overview of the developing landscape of low- and zero-GHG emission maritime fuels and the advantages and challenges of emerging clean fuel options.

What makes a good fuel?

An ideal maritime fuel would have all the following attributes:

- An efficient energy carrier. Energy carriers transport energy from one form to another and can be converted into other types of energy, like heat or light. Petroleum, hydrogen, and electricity are energy carriers, among many others.

- High energy content. The best fuels, especially for maritime applications where ships need to travel far distances without stopping to refuel, would release a lot of energy per amount of fuel used.

- Safe to use and store. Many people live and work between where fuels are produced, transported, stored, and loaded onto a vessel. Safety concerns include toxicity and combustibility of the fuel. The development and demonstration of alternative fuels for maritime uses must also demonstrate that fuels can be safely transported and stored.

- Produced at scale and cost competitive. Even if an alternative fuel option is technically feasible to power a ship, another key question is if it can be produced at an industrial scale to meet the demand of shipping and cruising, and whether the fuel can be moved around the world at a reasonable cost.

- Minimal environmental impacts. A viable alternative maritime fuel needs to have minimal environmental impacts across its entire production lifecycle. This means it would have low- or zero-GHG emissions, avoiding both carbon dioxide and other GHGs like methane or ozone-forming nitrogen. It should also have no particulate matter and other air pollutants detrimental to human health. Other environmental considerations include fuel spill consequences, land use change and other environmental impacts to produce the feedstock (the raw material needed to make the fuel).

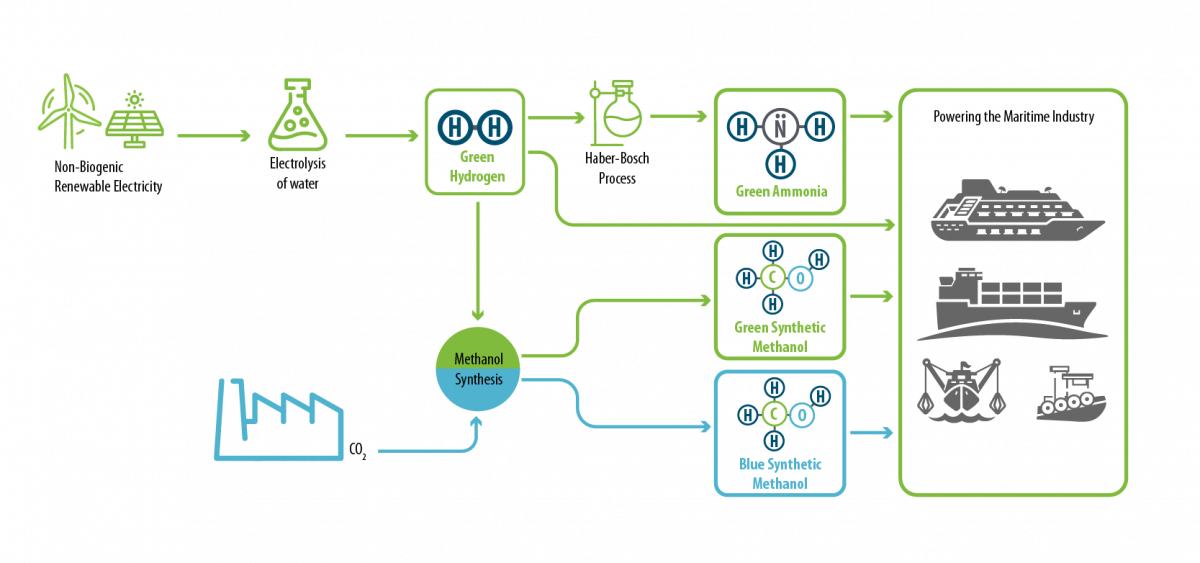

Not only are there a variety of fuel choices to assess using these attributes but the same fuel can be produced with different methods, adding to the choices. The methods are described by color. “Brown”, “gray”, and “black” fuels, like black hydrogen, use fossil fuels or coal in the production process. “Blue” fuels also use fossil fuels but they aim to trap and store the carbon emissions released in the production process, known as carbon capture and storage. “Green” is the term used to describe fuels that don’t produce harmful greenhouse gas emissions and use renewable energy in the production process.

Green alternatives are being researched and piloted around the world, but there is not one that currently meets all these requirements for the maritime industry. We walk through three of the emerging candidates below.

Which clean fuels are emerging for maritime applications?

Hydrogen is a chemical element. It is the lightest element in the periodic table, consisting of only one proton and one electron. It exists all around us as one of the elemental components of a very familiar substance: water (H2O). Hydrogen is an excellent energy carrier. It has the highest energy content of all chemical fuels when measured by mass at 120.2 MJ/kg, compared to heavy fuel oil at 40.2, methanol at 19.9, and ammonia at 22.5.1 It’s a viable clean fuel option because, when consumed in a fuel cell, the only by- product is water. It can be used in a variety of applications including long-duration energy storage, maritime fuels, back-up power, and propulsion of heavy-duty vehicles and vessels. In the port environment, hydrogen, fuel cells, and electrolyzers provide important decarbonization tools where other clean energy technologies may be lacking or cannot be easily deployed.

However, hydrogen rarely exists on its own and must be separated from other parts of a chemical compound containing hydrogen. In the case of water, it must be split from oxygen. Once separated, hydrogen can create electricity in a fuel cell. (Sources: “Hydrogen Fuel Basics” at Energy.gov; and “Hydrogen Explained” at U.S. Energy Information Administration).

In reality, hydrogen is a colorless gas but the production process is summarized by the rainbow. About 95% of all hydrogen produced today is “grey hydrogen”, produced with natural gas. “Green hydrogen” is produced through electrolysis, where renewable energy is used to decompose water into hydrogen and oxygen. The use of a renewable source of energy to produce hydrogen makes green hydrogen a zero-GHG emission source of fuel.

For an illustrated guide to the hydrogen rainbow, enjoy this Planet Money TikTok.

Example project:

Ferry passengers in San Francisco will ride the first U.S. Coast Guard-approved commercial hydrogen fuel cell ferry in the world. The SeaChange, as it’s called, started operating this fall and Port Commissioner Felleman checked it out.

You may be most familiar with ammonia as a pungent household cleaner you store underneath your sink, or a key ingredient in fertilizer. A lesser-known use of ammonia is its potential to be a green fuel propelling ships across the ocean. So how does it become a fuel? Let’s revisit high school chemistry. Ammonia as a chemical is NH3 — one nitrogen atom bonded to three hydrogen atoms. Liquid ammonia acts as a source of hydrogen that is more “energy dense” by volume — or otherwise contains twice as much hydrogen — as hydrogen in liquid form. And it’s easier to store than hydrogen. Ammonia is being researched both as a fuel itself that can be burned in new engines; and as a more efficient way to carry hydrogen. Ammonia could be carried as cargo aboard a ship and then converted to hydrogen to use in fuel cells. (Sources: “Ammonia—a renewable fuel made from sun, air, and water—could power the globe without carbon” — at Science.org ; and “Ammonia as Marine Fuel” at American Bureau of Shipping).

Ammonia is already produced on a global scale to make fertilizer. The current production process uses hydrogen taken from natural gas, creating what’s called “brown ammonia,” because it emits carbon dioxide, a GHG. Similar to green hydrogen discussed above, “green” ammonia (also called e-ammonia) is ammonia produced using renewable energy. Water is decomposed into hydrogen and oxygen and the hydrogen is then combined with nitrogen under pressure and high temperature.

Pilot projects for green ammonia production, engine use, and storage practices are rapidly progressing around the world, but it is not yet usable on an industrial scale

Example project:

A pilot project in Norway is exploring an ammonia-powered oil tanker.

Methanol (CH3OH) is an organic chemical. It has similar properties to ethanol, which can be made from corn and other plant materials and is widely used in blends of gasoline. Methanol is already available and used as a shipping fuel today; however, its future as a zero-GHG emission fuel depends on how it is produced.

Unlike hydrogen (H2) or ammonia (NH3), the chemical compound of methanol contains a carbon atom. This means that creating methanol involves carbon (CO2). Whether it can be a zero-GHG emission fuel depends on whether that carbon comes from a renewable or non-renewable source. Most methanol produced today is not zero-GHG emission as production uses natural gas. Low- or zero-GHG emission methanol can one of two types: bio-methanol or e-methanol. Bio-methanol is created from a biomass waste that has the carbon needed to make methanol, such as agricultural waste, sewage, or wood waste. E-methanol is created by combining green hydrogen and carbon dioxide from carbon capture, the process of removing carbon directly from the atmosphere or pulling it in as it’s released from a source. Carbon capture is a technology people are hopeful about but hasn’t yet been fully proven to work. In addition, the production process to produce low or zero-GHG emission methanol needs to be powered by renewable energy.

Example projects:

- Waterfront Shipping Company in Canada currently operates nine methanol-fueled ocean-going vessels to move bulk chemicals and petroleum products around the world.

- A.P. Moller – Maersk is partnering with companies around the world to boost production of green methanol by 2025.

| Advantages | Challenges | |

|---|---|---|

| Hydrogen |

Green hydrogen is the current cleanest marine fuel option due to zero carbon emissions and low outputs of NOx, Sox, and particulate matter. It only produces water as waste! The technology has been proven in smaller ships and now needs to be scaled up. Uses freshwater as a feedstock. While this may seem like a challenge in today’s warming world, hydrogen production is predicted to consume less water than the fossil fuel industry currently does. |

Storage must either be massive if it’s in gas form or must be cryogenic if it’s in liquid form Requires strict safety protocols because it is highly flammable |

| Methanol |

Methanol is easier to store and handle than both hydrogen and ammonia Easily biodegradable, it has a half-life in surface water of 1 – 7 days which means there could be less impact on marine life if a spill occurs Because methanol is a liquid fuel, it requires smaller modifications to existing ship engines and infrastructure than other alternative fuels |

Making methane requires carbon. Sustainably sourced carbon is a relatively small resource and the technology to capture CO2 from the air isn’t advanced enough yet. Methanol has a lower energy content that conventional fossil fuels, meaning that it will need about 2.54 times more storage than today’s fuels do. |

| Ammonia |

No carbon emissions when produced with renewable electricity and electrolysis Around 20 million tons of ammonia is already produced and transported around the globe so some infrastructure already exists |

It has a lower density than fuel oil so it would require more tank volume aboard ships It is highly toxic so extensive safety protocols are needed to protect those who will work around it |

How alternative fuels are made

What about wind, solar, and other technologies?

Green hydrogen, e-ammonia, and methanol represent a selection of the low- and zero-GHG emission fuels the maritime industry is exploring. Additional technologies and pilots are underway to increase energy efficiency of ships or enhance battery storage that could be combined with renewable fuels. For example, wind propulsion can be combined with other power sources to reduce fuel consumption. Solar power has not gained much traction for large ships as the energy generated and associated fuel savings is relatively small. (Source: “Wind and Solar Power for Zero Emissions Shipping” at Eco Marine Power).

Solar, wind, and other sources of renewable power are still a critical piece of the decarbonization puzzle as more clean energy sources are needed to power fuel production. As of 2019, there was 600 Gigawatts (GW) of solar capacity worldwide. By 2050, 2,000 – to 8,000 GW will be needed depending on carbon reduction ambitions. (Source: "Maritime Forecast to 2050", DNV).

How is the Port supporting the development of clean maritime fuels?

While the development of zero-GHG emission maritime fuels faces considerable challenges, this isn’t an entirely brand new topic for the Port of the Seattle — we’ve been involved in the development of Sustainable Aviation Fuels since 2008.

The Pacific Northwest is uniquely positioned to leverage its hydro, solar, and wind power resources to produce clean renewable energy and sustainable maritime fuels. The Port is not a fuel producer and does not own any vessel fueling infrastructure. However, the Port can take a leadership role in supporting the development of clean fuels and planning for infrastructure needed on Port property in the future to support the zero-emission transition.

The Port is working with partners to advance the development of green hydrogen in the Pacific Northwest, support supply chain development, and increase access for hard to decarbonize Port and maritime end uses. We’re involved in several studies to explore the potential of shifting from fossil fuel to clean hydrogen.

In 2020, a new partnership between the Port of Seattle, the Northwest Seaport Alliance, and Seattle City Light developed the Seattle Waterfront Clean Energy Strategy, a holistic plan to decarbonize the maritime industry in Seattle. The strategy is in development now and expected to be completed early by mid-2023.

Learn more:

- NextGEN (imo.org) offers a map to explore decarbonization initiatives around the globe

- The Getting to Zero Coalition is an initiative of Global Maritime Forum which is working towards full decarbonization of the maritime shipping industry by 2050. They have insight briefs on alternative fuels and reports on zero emission pilots around the world, among other materials